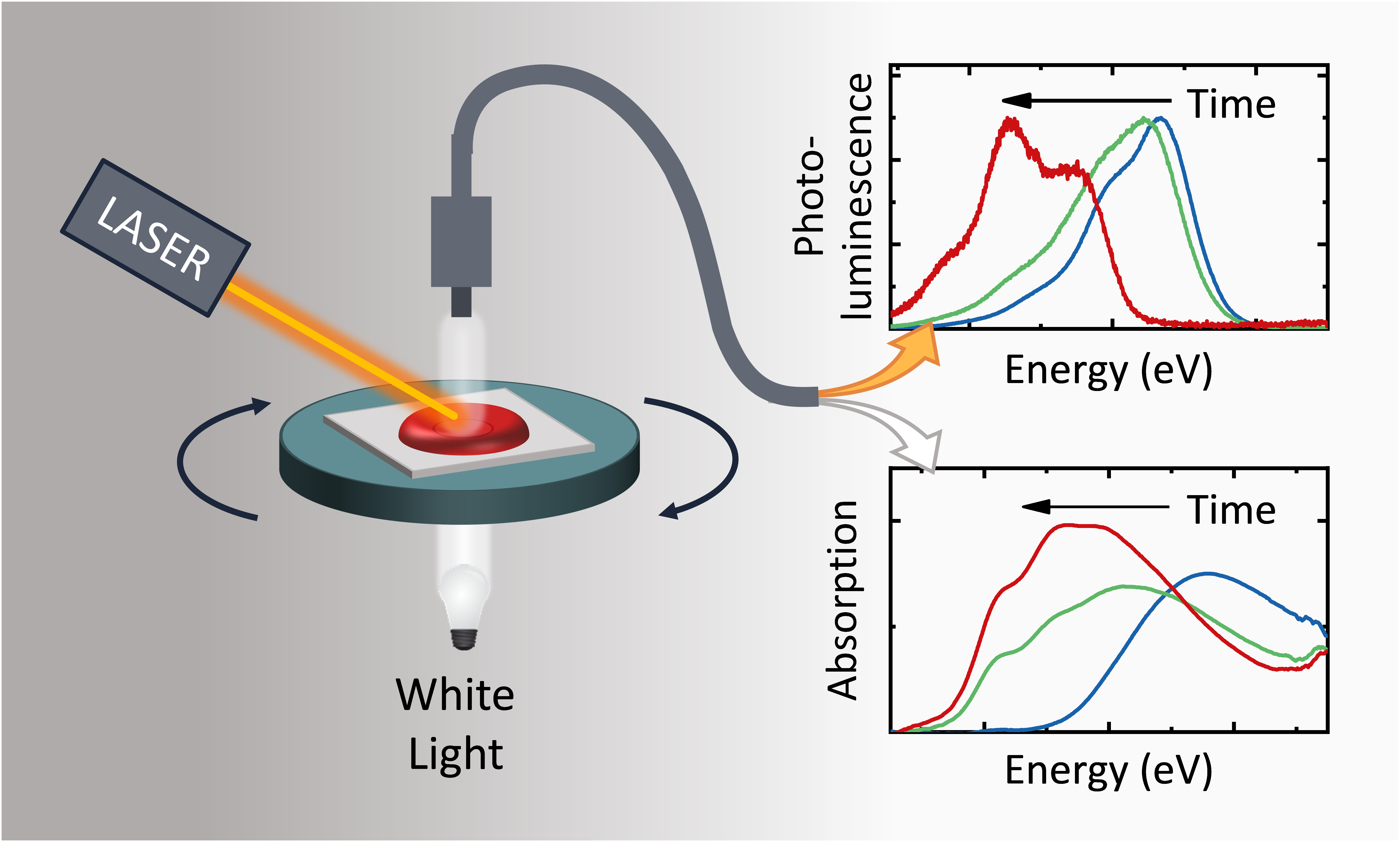

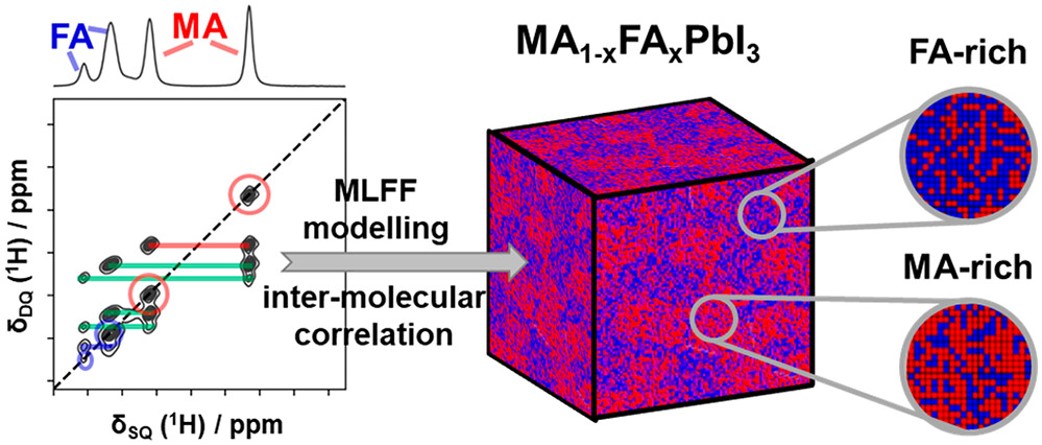

Recent developments in thefield of high efficiencyperovskite solar cells are based on stabilization of the perovskitecrystal structure of FAPbI3while preserving its excellentoptoelectronic properties. Compositional engineering of, forexample, MA or Br mixed into FAPbI3results in the desiredeffects, but detailed knowledge of local structural features, such aslocal (dis)order or cation interactions of formamidinium (FA) andmethylammonium (MA), is still limited. This knowledge is,however, crucial for their further development. Here, we shed lighton the microscopic distribution of MA and FA in mixedperovskites MA1−xFAxPbI3and MA0.15FA0.85PbI2.55Br0.45bycombining high-resolution double-quantum1H solid-state nuclear magnetic resonance (NMR) spectroscopy with state-of-the-artnear-first-principles accuracy molecular dynamics (MD) simulations using machine-learning force-fields (MLFFs). We show that ona small local scale, partial MA and FA clustering takes place over the whole MA/FA compositional range. A reasonable driving forcefor the clustering might be an increase of the dynamical freedom of FA cations in FA-rich regions. While MA0.15FA0.85PbI2.55Br0.45displays similar MA and FA ordering as the MA1−xFAxPbI3systems, the average cation−cation interaction strength increasedsignificantly in this double mixed material, indicating a restriction of the space accessible to the cations or their partialimmobilization upon Br−incorporation. Our results shed light on the heterogeneities in cation composition of mixed halideperovskites, helping to exploit their full optoelectronic potential.